Gear Up for Every Journey.

Rugged mobile accessories engineered for the Australian outback—and your everyday adventures.

Shop the RangeOur Products

Screen Protectors

- • Scratch-proof 9H glass

- • Easy bubble-free install

- • Edge-to-edge coverage

Durability & Technology

Every product begins with a single question: will it survive the red dust of the outback? Our engineers push prototypes far beyond typical consumer-grade limits to guarantee field-ready reliability.

Aviation-Grade Aluminium Frames

We CNC-machine each wireless charger from 6061-T6 aluminium for optimal heat dissipation and structural integrity.

Impact-Absorb™ Polymer

Our proprietary polymer absorbs up to 75 % more impact energy than standard TPU, verified by SGS drop tests.

Bluetooth 5.3 & aptX™

Headsets utilise the latest Qualcomm chipsets, delivering low-latency audio with multi-device pairing.

Sustainability

Plant-Based Packaging

100 % compostable mailers

Recycled Materials

43 % of product plastics

Carbon-Neutral Shipping

Offset 12 t CO₂ in 2023

Water-Based Inks

Zero VOC emissions

Custom Mount Design Process

1. Requirement Capture

We gather vehicle specs, mounting points and user ergonomics.

2. 3D Modelling

Engineers create a CAD model, ensuring airflow and cable management.

3. Prototype & Test

We 3D-print prototypes for drop, vibration and UV exposure tests.

4. Production & QA

Injection moulding or CNC machining executed with ISO 9001 QA checkpoints.

5. Delivery & Support

Mounts shipped with installation guides and lifetime customer support.

What Our Customers Say

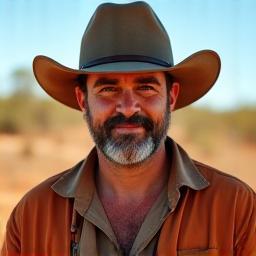

Meet the Crew

Lachlan Ward

Founder & CEO

Former aerospace engineer passionate about rugged consumer tech.

LinkedIn

Martin O’Connor

Lead Industrial Designer

Award-winning designer blending ergonomics with aesthetics.

LinkedIn

Aisha Rahman

QA & Compliance Manager

Ensures every product meets ISO 9001 and RoHS standards.

LinkedInGet in Touch

Address

58 Mcleay Street, Suite 4B

East Melbourne, VIC 3002

Australia

Phone

support@outbackmobilegear.com.au

Mon–Fri 9 am–5 pm AEST